|

Note: If you are not at all familiar with basic electronics, you might find it easier to follow parts of this chapter if you read chapter 12 first.

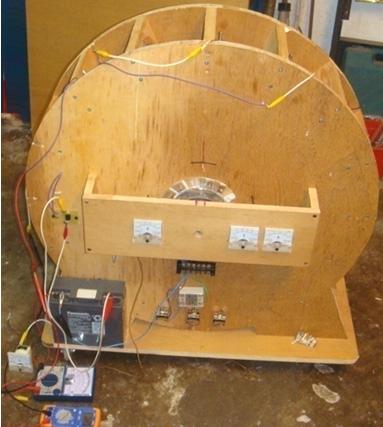

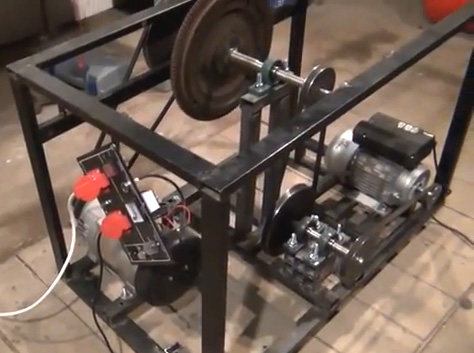

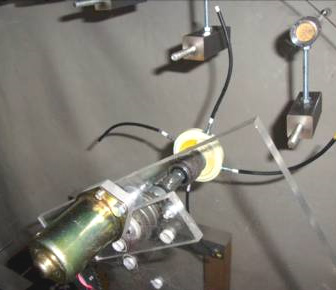

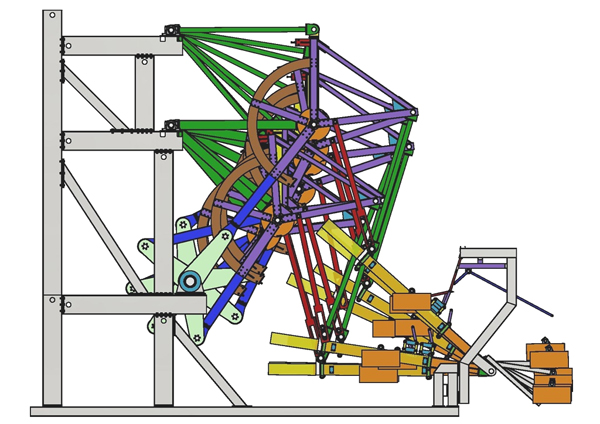

It is generally not realised that excess energy can be obtained from pulsing a flywheel or other gravitational device.  This fact has recently been stressed by Lawrence Tseung who refers to the extra energy obtained in this way as being “Lead-out” energy. This gravitational feature has been part of university Engineering courses for decades, where it has been taught that the loading stress on a bridge caused by a load rolling across the bridge is far less than the stress caused if that same load were suddenly dropped on to the bridge. This impulse technology has been known for some time and it is demonstrated driving a canoe in the video at this location but Lawrence points out the potential for using it as a method for gaining excess energy for practical use. In October 2009, Lawrence and his band of helpers ran public demonstrations of an early prototype electrical pulsing system which produces excess output energy of COP = 3.4, that is, with 3.4 times more output energy than the user has to put into it to make it work:  Video. Lawrence is busy developing this device further as he intends to construct one with a output energy excess of several kilowatts. Behind this device is Lawrence's "Lead-out" theory and for this he suggests a simple arrangement to demonstrate the principle. He presents the case of a rotor which has two substantial weights contained in two cylinders attached to the rotor:  As the disc rotates, the ball falls down the length of the tube. At one end, the tube has a rigid cap which causes a significant impact when the ball hits it. The other end of the tube is padded and that cushions the impact which causes a net imbalance in the impacts and that maintains the rotation. There is a prototype implementation on YouTube but the implementation is not adequate and the disc stops rotating after five minutes. The YouTube video slot is located here and there are two significant problems with that particular build. Firstly, the tube rotation is too slow to be effective and instead of the weight falling under gravity and acelerating to a good speed before the impact, the weight just rolls gently down a minor slope and does not make a major impact. Secondly, the weights are far too small for the size of the wheel and there are only two weights providing impacts very widely spaced apart as the wheel rotates only slowly. One man made a ten-foot version and it rotated steadily for ten months after which time his wife insisted that it be taken apart as it was too noisy. I would suggest some modifications to the wheel as Lawrence is far too busy with developing his COP>1 pulse implementation. Firstly, the movement of each weight should be delayed until the tube is much nearer the vertical. This can be achieved by curving part of the tube like this:  This way, the ball does not start rolling until the main part of the tube is near vertical. This allows a much greater acceleration and impact. The weighted ball should be much larger, say 2" (50 mm) in diameter and made of lead, in order to generate a significant thrust. Also, the cushioned ends of the tubes should be aligned with the pivot of the wheel so that any residual impact does not generate a turning force in the wrong direction. there is a negative turning effect due to the lever arm of the bottom weight. This turning force is only there for a small arc of rotation as the weight will roll inwards as soon as the tube section rises above the horizontal and as the tube then transitions into a circular curve, the movement inwards is gentle. It probably would be better if the tubes were angled slightly more in the clockwise direction, rather than exactly as shown in the diagram. Secondly, there should be eight tubes on the disc, four on each side and one side staggered by 45 degrees so that there is a driving impact every 45 degrees instead of the 180 degrees of the version shown in the YouTube video. With that arrangement of four times as many impacts, each substantially greater, and no significant reverse impacts, the wheel has a much better chance of successful rotation without needing to be particularly large. The wheel itself should not be light as it acts as a flywheel and a pulsed flywheel has already been shown to produce excess power. The wheel bearings should be ball races and not the closed variety because those ones are packed with grease and have a serious resistance to rotation. Instead, the open-sided variety of ball bearing should be used as they rotate very freely. Using straight tubes for illustration, each tube could be like this:  Here, a wood disc is fitted to each end of a piece of plastic tube and held securely in place with screws or bolts which pass through small holes drilled in the plastic pipe and screw into the wooden disc. A piece of thick sponge is glued to the disc at one end and the heavy weight inside the tube is not a tight fit so that it can move very freely inside the tube. Four of these tubes are fitted to each side of each disc used in the device as shown here:  The four tubes attached to the back of the disc are 45 degrees away from the tubes mounted on the front of the disc. Each tube is attached securely in place with straps which pass through the disc and are secured on the far side. The tubes can also be glued in place to further strengthen the attachment. These eight tubes give an unbalanced impact for every 45 degrees of rotation. If two of these discs are attached to a common rotor shaft, then the second disc can be positioned 22.5 degrees around from the first one. That arrangement gives an unbalanced impact for every 22.5 degrees of rotation. If three discs were placed on a common rotor shaft and evenly positioned, then there would be an unbalanced impact every 15 degrees of rotation, which is 24 impacts per rotation. A two-disc arrangement might look like this:  If the rotor spins well, then it would be worth while attaching a series of magnets to the discs, being careful to keep each disc perfectly balanced. One or more air-core coils can then be used to determine if current can be drawn from the device without stopping the rotation. The coils should not have a magnetic core as that would cause a major drag on the rotation whether current was being drawn or not.  The Chas Campbell System. Recently, Mr. Chas Campbell of Australia demonstrated electrical power gain with a flywheel system which he developed:  But what this diagram does not show, is that a couple of the drive belts are left with excessive slack. This causes a rapid series of jerks in the drive between the mains motor and the flywheel. These occur so rapidly that they do not appear noticeable when looking at the system operating. However, this stream of very short pulses in the drive chain, generates a considerable amount of excess energy drawn from the gravitational field. Chas has now confirmed the excess energy by getting the flywheel up to speed and then switching the drive motor input to the output generator. The result is a self-powered system capable of running extra loads. Let me explain the overall system. A mains motor of 750 watt capacity (1 horsepower) is used to drive a series of belts and pulleys which form a gear-train which produces over twice the rotational speed at the shaft of an electrical generator. The intriguing thing about this system is that greater electrical power can be drawn from the output generator than appears to be drawn from the input drive to the motor. How can that be? Well, Mr Tseung’s gravity theory explains that if a energy pulse is applied to a flywheel, then during the instant of that pulse, excess energy equal to 2mgr is fed into the flywheel, where “m” is the mass (weight) of the flywheel, “g” is the gravitational constant and “r” is the radius of the centre of mass of the flywheel, that is, the distance from the axle to the point at which the weight of the wheel appears to act. If all of the flywheel weight is at the rim of the wheel, the “r” would be the radius of the wheel itself. This means that if the flywheel (which is red in the following photographs) is driven smoothly at constant speed, then there is no energy gain. However, if the drive is not smooth, then excess energy is drawn from the gravitational field. That energy increases as the diameter of the flywheel increases. It also increases as the weight of the flywheel increases. It also increases if the flywheel weight is concentrated as far out towards the rim of the flywheel as is possible. It also increases, the faster the impulses are applied to the system. However, Jacob Byzehr points out that another mechanism comes into play even if all of the belts are correctly tensioned. The effect is caused by the perpetual inward acceleration of the material of the flywheel due to the fact that it rotates in a fixed position. He refers to it as being ‘the rule of shoulder of Archimedes’ which is not something with which I am familiar. The important point is that Chas Campbell’s system is self-powered and can power other equipment Now take a look at the construction which Chas has used:  You notice that not only does he have a heavy flywheel of a fair size, but that there are three or four other large diameter discs mounted where they also rotate at the intermediate speeds of rotation. While these discs may well not have been placed there as flywheels, nevertheless, they do act as flywheels, and each one of them will be contributing to the free-energy gain of the system as a whole. A replication video with 750 watts input and 2340 watts output is here and this implementation does not appear to have a heavy flywheel as you can see from this picture, although the largest pulley wheel looks as if it contains considerable weight:  Jacob Byzehr. In 1998, Jacob lodged a patent application for a design of the type shown by Chas Campbell. Jacob has analysed the operation and he draws attention to a key design factor:  Jacob states that a very important feature for high performance with a system of this kind is the ratio of the diameters of the driving and take-off pulleys on the shaft which contains the flywheel, especially with systems where the flywheel rotates at high speed. The driving pulley needs to be three or four times larger than the power take-off pulley. Using Chas’ 1430 rpm motor and a commonly available 1500 rpm generator, the 12:9 step-up to the shaft of the flywheel gives a satisfactory generator speed while providing a 3.27 ratio between the 9-inch diameter driving pulley and the 2.75” diameter power take-off pulley. If a generator which has been designed for wind-generator use and which has it’s peak output power at just 600 rpm is used, then an even better pulley diameter ratio can be achieved. The Self-powered Generator of José Luis García del Castillo In 1998, Spanish patent ES 2,119,690 was granted to José Luis García del Castillo. I suspect that the auxiliary generators shown in the patent are only there to get the patent accepted by the patent examiner, rather than because they are actually needed. If that is correct, then the design is almost the same as Chas Campbell’s design, although built in a more compact form:  As Jacob Byzehr points out, an energy gain is achieved through inertial acceleration caused by having the pulley wheel “A” attached to the flywheel shaft, larger than the pulley wheel “B” attached to the shaft of the generator. As drawn, there is a major difference in those diameters. Here is an attempted translation of the patent: AUTONOMOUS ENERGY REGENERATION SYSTEM  Abstract The system comprises an electric motor drive (1), a main generator (2), auxiliary generators (3), a battery (4), a charging regulator (5), and a speed regulator (6). The system is intended to generate its own operating power, and provide an extra supply for other purposes. The present invention refers to a self-contained system of energy regeneration, which in addition has several advantages set out below. Background of the invention It has been known for many years, how to construct machines which can generate electric current. These are known by the generic name of "electric power generators", consisting of rotating machine that transforms mechanical power into electrical power as a result of alternative action between a magnetic field and a moving conductor. However, the various types of generator which make up the current state of the art, require the help of a motor, which transforms mechanical power into electrical energy, and that motor requires an independent power source which must be supplied continuously. Thus, a system capable of generating its own power supply as well as providing an extra power supply for other purposes, is not known in the current state of the art. Summary of the invention The applicant for the present patent has designed an self-contained energy regeneration system, capable of producing its own operating energy in addition to generating a surplus which can be used in electrical networks using voltage converters required for any electrical installation, whether in homes, offices, warehouses etc.., with it is possible to reach places where it is difficult to install the power grid, allowing its use as an alternative source of energy other than solar or wind power. Other applications would be in the automotive field, as a power source for motorcycles, cars, etc. by connecting the system to the propelling motor, and thus achieving the necessary motion of the vehicle. Overall, the system is comprised of the following basic components: